| Home > Maintenance & Mods (L322) > Reservoir & Valve Block Removal |

|

|

|

| Joe90 Member Since: 29 Apr 2010 Location: Hampshire Posts: 6419

|

Ongoing efforts to foil "pressure static" fault - Welshdragon's replacement of the pressure switch didn't work, so I had a look at the valve block.

9. Undo all pipes using 12mm spanner (noting positions), release the three electrical connectors. Cover the neds of the pipes to keep dirt and dust out. 10. Valve block is held in place by three 10mm nuts fixed to rubber mounted bolts. Mine was only hanging on by one, so I pulled it off and removed to bench. If yours is as rusty as mine just getting on the nuts or turning them will probably break the rubber mounts. Don't worry, all is not lost if this happens.

11. Release electrical connector to pressure switch.

This section is for side steps a. Undo the 13mm M8 bolt for each leg of the side steps. If you are unlucky, like me, the nuts will shear. Both did. b. Place a stand or support under the rear end of the side step, to prevent it falling on you. c. Undo the two 10mm bolts on each leg which are bolted vertically to the inner sill. If you are lucky, like me, 3 of the 4 will undo, and only one will shear. The front ones are clear of the reservoir, whilst the rear ones will appear to foul the tank, but they will undo and fall out with a bit of wiggling. d. Now manoeuvre the rear of the side step away from the car to give access to the reservoir 12. Support the reservoir, and undo the four 10mm bolts fixing it to the inner sill.

13. Gently lower as the rear pipes and compressor pipe are still attached by two clips on top.

14. Unclip the pipes and remove reservoir from vehicle. That was enough for one evening. ################################################## Up the following morning and commandeered the kitchen table to strip down the valve block. It's a �400+ part to replace so take care 1. Using 10mm spanner and maybe pliers on the other end, remove the three mounting bolts, and set aside. 2. Have a good clean up of the valve block (I used an old toothbrush and some paper towel with WD40). This just reduces the change of getting dust and dirt into the valve chambers. 3. Using correct sized torx driver undo all 10 of the screws holding the solenoids in place. These can be very rusty too. One was so corroded I was again lucky to have enough of the star left to undo it. Fortunately they are open screws so not too tight. 4. Clean up again to remove bits of rust etc. 5. Lift each chamber cover in turn to reveals the innards. The two outer chambers are are mirror image of each other, with the plungers at one end red and the other black. The centre chamber allows air to pass from the reservoir to the "corners" (I think)

6. Carefully remove all the parts in sequence so they can go back where they came from and inspect. I was hoping to find a horror of some description, having seen the state of RS200Custom's innards but mine all seemed in good clean nick. Everything seemed to move and work as it should. Tested the centre one on a battery and it clicked away quite happily opening the valve at the top.

7. Clean up where needed, no lubricants needed inside, and rebuild the valve block. Repairing the rubber mounted bolts I hadn't realised that there was a bolt at either end of these things, the other end fixed to the reservoir flange. You need the reservoir out to remove these completely, but you could do the repair in situ with valve block removed. Once the nuts were undone on the reservoir each bolt needed a hefty tap with a hammer to release it. A simple removal of all rust and dirt, a good sand down of mating surfaces with green coarse paper, and then applied viscous superglue (purchased from Tooltime) and held each one til set. Leave for a while, then refit to reservoir flange. 8. Slide the rebuilt valve block onto the rubber mounted bolts and fix. It is easier to do this off the car than on. 9. Refit the pipe from the reservoir to the valve block. (12mm) Repairing damage done to Side Step Mountings The more accurate among you would be able to perform a perfect sheared off nut removal and recover the original thread for the captured nuts. Not me. Too clumsy. Drilled out with cobalt drills to 8mm thus removing the thread. However, for once, LR provided useful drain holes in the chassis just close enough to provide access from the inside. Using a variety of methods (cable tie, sticky tape, thin plastic) I was able to manoeuvre a 40mm M8 bolt down through each hole for the main leg mountings. I didn't bother with the 10mm one I sheared off, hopefully one will be sufficient to take the weight of my svelt figure Enough for this day, other things to do... ################################### Refit Note, all nuts and bolts run up and down their partners to make it easy to fit, and treated with copper ease and grease as needed. 1. Bring reservoir to car and and refit rear pipes and compressor pipe to valve block. Again, easier to do this off the car than on. 2. Clip the pipes back onto the reservoir 3. Offer reservoir up and fix with a couple of the 10mm bolts for now. Do not tighten just yet. (This because of side steps) Refit SideSteps a. Manoeuvre side step into position, first fixing loosely the two main chassis leg bolts, then the side bolts. By not fixing firm the reservoir, I had a little bit of play to assist with getting the rear leg 10mm bolts into position, even using the reservoir to hold then in place. b. "Hand" tighten all bolts and ensure that side step is correctly positioned, then tighten up. 4. Fit remaining reservoir bolts, ensure rear pipes are not trapped, then tighten up. 5. Refit remaining front pipes 6. Refit three electrical connectors (the front one is a fiddle!) You can't get these wrong, due to number of pins, length of cable and colour coding. 7. Refit electrical connector to pressure sensor. 8. Refit tank cover. Make sure it is the correct position, especially over the two bolts by the exhaust, before fitting any bolts. 9. Refit heat shield 10. Liberal spray of preferred protective lubricant over valve block, dabs of grease etc. 11. Replace plastic cover over valve block. 12. Remove the two safety jacks 13. Start car, IIDTool, Reenable EAS. 14. Then follows some fiddling about, jacking up, removing axle stands, driving off blocks, testing heights etc. No fault codes yet, but will probably see one tomorrow Experience is the only genuine knowledge, but as time passes, I have forgotten more than I can remember Volvo V70 P2 2006 2.4 Petrol 170bhp Estate SE MG Midget Mk1 1962 Previous: L322 Range Rover TDV8 3.6 2008; L322 Range Rover TD6 3.0 2002; P38A Range Rover V8 1999 |

||||||||||||

|

| Joe90 Member Since: 29 Apr 2010 Location: Hampshire Posts: 6419

|

I forgot to mention, I also tested resistance on a few things:

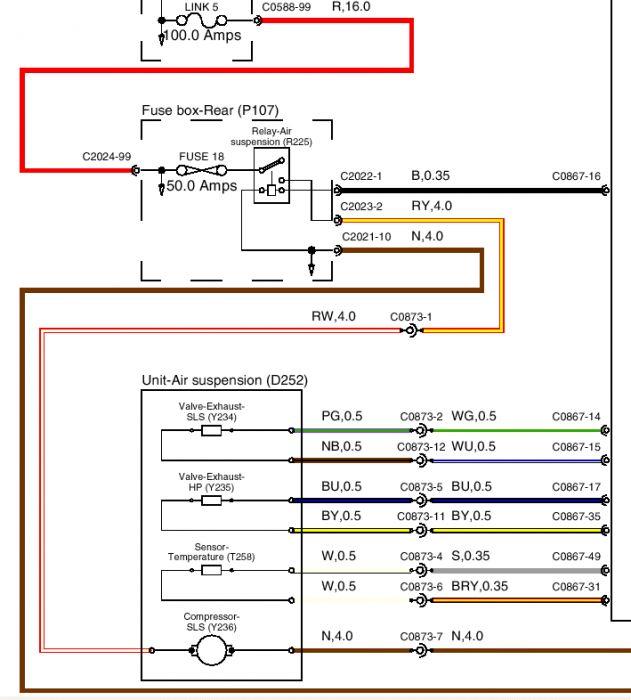

shows SLATE and RED/BLACK/YELLOW from sensor ??? However at least something happened, demonstrating there was a connection in the wire ? . Experience is the only genuine knowledge, but as time passes, I have forgotten more than I can remember Volvo V70 P2 2006 2.4 Petrol 170bhp Estate SE MG Midget Mk1 1962 Previous: L322 Range Rover TDV8 3.6 2008; L322 Range Rover TD6 3.0 2002; P38A Range Rover V8 1999 |

||||

|

| Haylands Member Since: 04 Mar 2014 Location: East Yorkshire Posts: 8518

|

Jo,

|

||

|

| Joe90 Member Since: 29 Apr 2010 Location: Hampshire Posts: 6419

|

Thanks Haylands - another good tip to add to the list to try and solve this annoyance |

||

|

| stan Site Moderator Member Since: 13 Jul 2010 Location: a moderate moderated moderator moderating moderately in moderation Posts: 35613

|

wikified . |

||

|

| Weejock Member Since: 31 Dec 2011 Location: UK Posts: 418

|

That's the wrong diagram for the pressure sensor, it shows the compressor temperature sensor and valves in the compressor. You want the next page of the manual |

||

|

| Joe90 Member Since: 29 Apr 2010 Location: Hampshire Posts: 6419

|

Oh well, it lasted a day before it faulted again. Onto the next fix |

||

|

| paulmoran2 Member Since: 27 Nov 2013 Location: Leeds Posts: 1422

|

Joe90...sorry to hijack, but you say that if the car is on axles stands and you deflate the susp airbags, the wheels will lift?...is that on all years as I thought that the system only allowed wheels to raise when under weight from gravity ( ie when car pushes them down)?

|

||

|

| Joe90 Member Since: 29 Apr 2010 Location: Hampshire Posts: 6419

|

I only had axle stands under one side of the car, and with this side wheels up on 4" blocks, so the tilt as the other side went right down may have caused this effect. That said there was no weight on the axle stands when I started to deflate and the wheels were off the blocks when finished, so there must have been a bit of "Citroen" effect going on.

|

||

|

| paulmoran2 Member Since: 27 Nov 2013 Location: Leeds Posts: 1422

|

Got'it. Ta. Was hoping wheel swapping had got easier

|

||

|

| Haylands Member Since: 04 Mar 2014 Location: East Yorkshire Posts: 8518

|

Jo Did you check the reed valve... could be a free fix!! Pete __________________________________________________ 2014 L405 Autobiography SDV8 4.4 Loire Blue Ebony interior 2012 L322 Autobiography 5.0 Supercharged Ipanema Sand Sold 2011 L322 Vogue SE 4.4 TDV8 Baltic Blue. Sold 2002 L322 Vogue 4.4 V8 Epson Green (Fatty Offroader) Sold -Click for Project Fatty off roader- |

||

|

| Welshdragon Member Since: 20 Jan 2012 Location: here and there...but not where I should be Posts: 1901

|

And after all that work too |

||

|

| Joe90 Member Since: 29 Apr 2010 Location: Hampshire Posts: 6419

|

@ Welshdragon

|

||

|

| pcourtney Member Since: 14 Jan 2020 Location: Stansted Posts: 900

|

when you remove the head off the wabco compressor, you should see the flat reed ( metal) valve shown below as you turn it over

this thin metal flap is called the Reed Valve Haylands read somewhere that the "pressure static" fault can be attributed to the reed valve on top of the compressor piston which can remain stuck open, a small bend of the metal and the "Pressure Static" fault cleared |

||||

|

|

|

| All times are GMT + 1 Hour |

< Previous Topic | Next Topic > |

Posting Rules

|

Site Copyright © 2006-2025 Futuranet Ltd & Martin Lewis

![]()