| Home > Maintenance & Mods (L322) > Reservoir & Valve Block Removal |

|

|

|

| Joe90 Member Since: 29 Apr 2010 Location: Hampshire Posts: 6414

|

Ongoing efforts to foil "pressure static" fault - Welshdragon's replacement of the pressure switch didn't work, so I had a look at the valve block.

|

||||||||||||

|

| Joe90 Member Since: 29 Apr 2010 Location: Hampshire Posts: 6414

|

I forgot to mention, I also tested resistance on a few things:

|

||||

|

| Haylands Member Since: 04 Mar 2014 Location: East Yorkshire Posts: 8353

|

Jo,

|

||

|

| Joe90 Member Since: 29 Apr 2010 Location: Hampshire Posts: 6414

|

Thanks Haylands - another good tip to add to the list to try and solve this annoyance |

||

|

| stan Site Moderator Member Since: 13 Jul 2010 Location: a moderate moderated moderator moderating moderately in moderation Posts: 35465

|

wikified . |

||

|

| Weejock Member Since: 30 Dec 2011 Location: UK Posts: 418

|

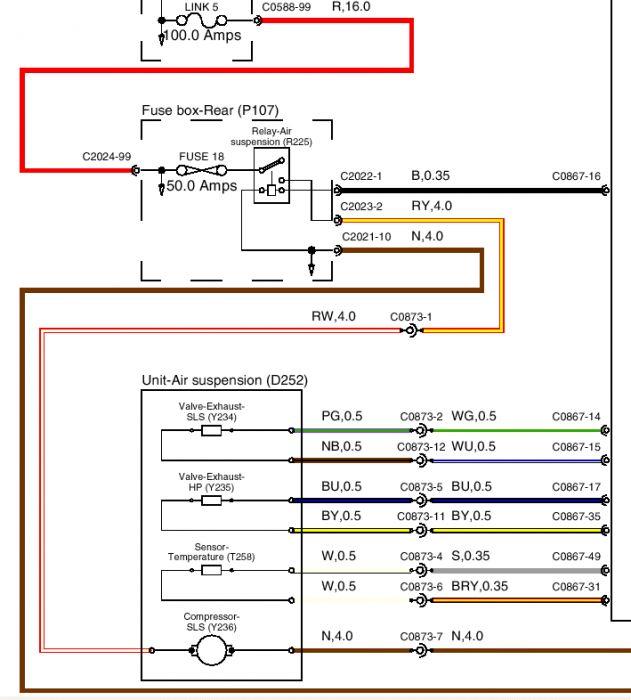

That's the wrong diagram for the pressure sensor, it shows the compressor temperature sensor and valves in the compressor. You want the next page of the manual |

||

|

| Joe90 Member Since: 29 Apr 2010 Location: Hampshire Posts: 6414

|

Oh well, it lasted a day before it faulted again. Onto the next fix |

||

|

| paulmoran2 Member Since: 27 Nov 2013 Location: Leeds Posts: 1422

|

Joe90...sorry to hijack, but you say that if the car is on axles stands and you deflate the susp airbags, the wheels will lift?...is that on all years as I thought that the system only allowed wheels to raise when under weight from gravity ( ie when car pushes them down)?

|

||

|

| Joe90 Member Since: 29 Apr 2010 Location: Hampshire Posts: 6414

|

I only had axle stands under one side of the car, and with this side wheels up on 4" blocks, so the tilt as the other side went right down may have caused this effect. That said there was no weight on the axle stands when I started to deflate and the wheels were off the blocks when finished, so there must have been a bit of "Citroen" effect going on.

|

||

|

| paulmoran2 Member Since: 27 Nov 2013 Location: Leeds Posts: 1422

|

Got'it. Ta. Was hoping wheel swapping had got easier

|

||

|

| Haylands Member Since: 04 Mar 2014 Location: East Yorkshire Posts: 8353

|

Jo Did you check the reed valve... could be a free fix!! Pete I now have permission from the boss to use Y.O.L.O. Enjoy life __________________________________________________ 2014 L405 Autobiography SDV8 4.4 Loire Blue Ebony interior 2011 L322 Vogue SE 4.4 TDV8 Baltic Blue. Sold 2012 L322 Autobiography 5.0 Supercharged Ipanema Sand Sold 2002 L322 Vogue 4.4 V8 Epson Green (Fatty Offroader) Sold -Click for Project Fatty off roader- |

||

|

| Welshdragon Member Since: 20 Jan 2012 Location: here and there...but not where I should be Posts: 1899

|

And after all that work too |

||

|

| Joe90 Member Since: 29 Apr 2010 Location: Hampshire Posts: 6414

|

@ Welshdragon

|

||

|

| pcourtney Member Since: 14 Jan 2020 Location: Stansted Posts: 835

|

when you remove the head off the wabco compressor, you should see the flat reed ( metal) valve shown below as you turn it over

|

||||

|

|

|

| All times are GMT |

< Previous Topic | Next Topic > |

Posting Rules

|

Site Copyright © 2006-2025 Futuranet Ltd & Martin Lewis

![]()