| Home > Maintenance & Mods (L322) > Correct procedure when installing new struts |

|

|

|

| dingg1 Member Since: 29 Jun 2013 Location: PORTUGAL Posts: 1368

|

Just leave the wheels off and jack the hubs up to normal road height, tighten as required. Job done.

|

||

|

| JayGee Member Since: 27 Jul 2021 Location: London Posts: 3283

|

That seems to refer to installing new bags to an existing strut. When I did mine the only things of note were to lift the whole car at the front to eqalise the tension on the ARB, mark the strut top nuts with some felt tip as they are in slots to trim camber, note the way the ABS wire goes as it's easy to get it on wrong. I torqued everything with the wheels off as there are no bushings under tension so didn't see the point. I also released the air from each bag by carefully loosening the connector on the strut ( which I reused). It's all pretty simple realy. 2012 TDV8 Vogue (L322) |

||

|

| dingg1 Member Since: 29 Jun 2013 Location: PORTUGAL Posts: 1368

|

Jay is correct

|

||

|

| Scouse Exile Member Since: 09 Dec 2022 Location: East Midlands Posts: 405

|

No it’s ok. The procedure described is for replacing the whole strut.

|

||

|

| Scouse Exile Member Since: 09 Dec 2022 Location: East Midlands Posts: 405

|

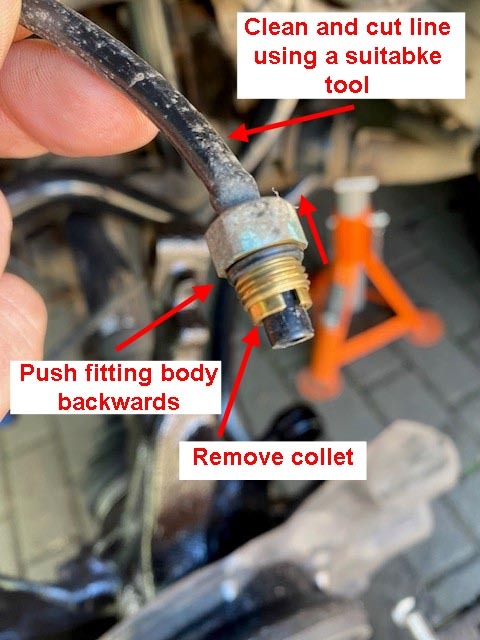

Its also worth noting that for the parts that I sourced through Island 4x4 at least (could be different for other suppliers), that the air fitting on the new parts is PUSH FIT ONLY and the connector should not be removed from the strut or it could invalidate your warranty.

|

||

|

| JayGee Member Since: 27 Jul 2021 Location: London Posts: 3283

|

You push the hose in and tighten it down with the brass fitting if you are trimming the hose. Or as I did I just removed the whole fitting from the old strut and screwed it in to the new one. Can't remember encountering any washers on the ARB drop links. 2012 TDV8 Vogue (L322) |

||

|

| dingg1 Member Since: 29 Jun 2013 Location: PORTUGAL Posts: 1368

|

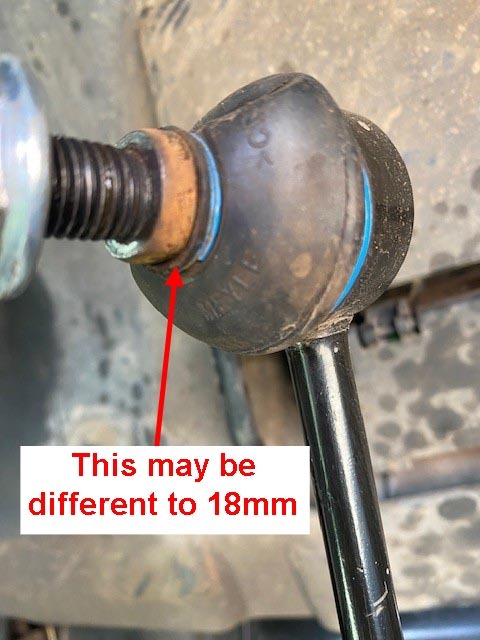

Drop links are meant to have a washer 👍 |

||

|

| Weegie Member Since: 09 Jun 2014 Location: East Sussex Posts: 3255

|

According to RAVE the washer is a hardened one:

|

||

|

| JayGee Member Since: 27 Jul 2021 Location: London Posts: 3283

|

Can't remember how I did it when I changed the struts but the ARB and droplinks were replaced last summer by a well known Hampshire specialist so I assume they did it correctly. 2012 TDV8 Vogue (L322) |

||

|

| Scouse Exile Member Since: 09 Dec 2022 Location: East Midlands Posts: 405

|

Yea that’s the problem, I also used a reputable Land Rover specialist and the washer is absent. It may be the case that the washers were missing when they changed the NS drop link and therefore didn’t fit one as the new drop links do not come with one.

|

||

|

| Scouse Exile Member Since: 09 Dec 2022 Location: East Midlands Posts: 405

|

Just an update to close this one off.

|

||||||||||||

|

| Ian Donkin Member Since: 17 Aug 2010 Location: A Yorkshireman in Surrey Posts: 107

|

Excellent tips and write up - in case anyone needs additional collets, I believe they are called Voss connectors (or certainly Voss fittings); I broke one on a former Mercedes I owned with air suspension and they use the same system.

|

||

|

| Scouse Exile Member Since: 09 Dec 2022 Location: East Midlands Posts: 405

|

Absolutely correct Ian, thank you. Couldn't think of the term. Hopefully helps someone. J |

||

|

| JayGee Member Since: 27 Jul 2021 Location: London Posts: 3283

|

|

||

|

|

|

| All times are GMT + 1 Hour |

< Previous Topic | Next Topic > |

Posting Rules

|

Site Copyright © 2006-2025 Futuranet Ltd & Martin Lewis

![]()