| Home > Maintenance & Mods (L405) > L405 Front Lower Arms Replacement - ball joint splitter tool |

|

|

|

| Cam-Tech-Craig Member Since: 04 Aug 2011 Location: Gloucestershire Posts: 16334

|

They are next level arn't they! |

||

|

| Haylands Member Since: 04 Mar 2014 Location: East Yorkshire Posts: 8521

|

Just had a look at it on eBay, yep, that'll get the job done...!!! |

||

|

| Gremlin500 Member Since: 11 Mar 2022 Location: Newcastle, UK Posts: 1667

|

Sorry all, it was Amazon I got it from, due to faster delivery possible.

|

||

|

| Gremlin500 Member Since: 11 Mar 2022 Location: Newcastle, UK Posts: 1667

|

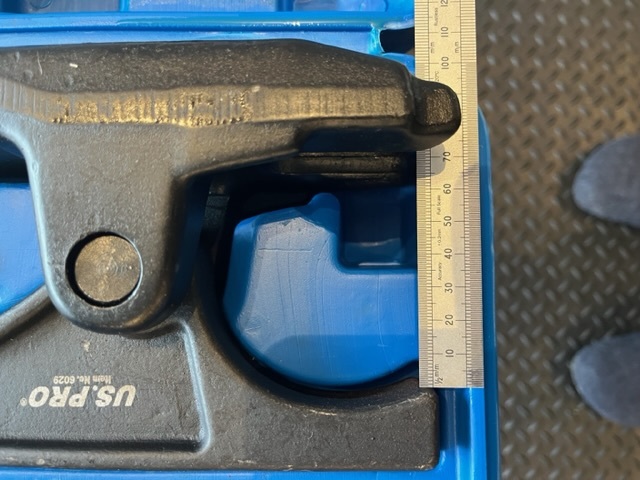

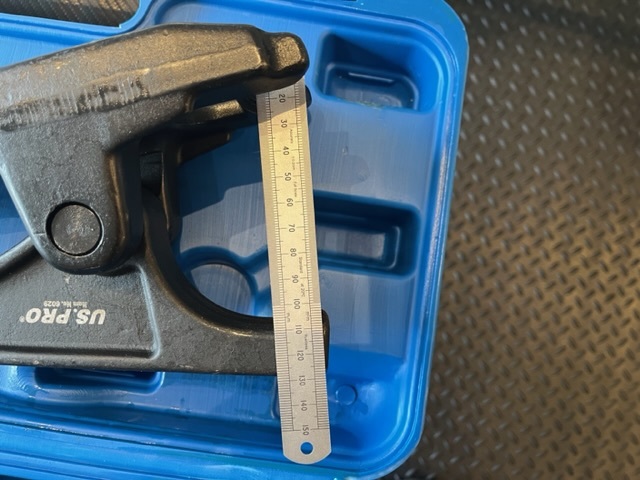

Quick pic:

|

||||

|

| grayst01 Member Since: 08 May 2022 Location: Glasgow Posts: 105

|

I’m currently looking at renewing all front suspension parts on my 2012 L322 and with the ball joints being a known ‘issue’ does anyone know if this tool would also be usable for the 322? I have been looking at having the local indy doing this for me solely down to the horror stories with the ball joints… thanks in advance |

||

|

| Gremlin500 Member Since: 11 Mar 2022 Location: Newcastle, UK Posts: 1667

|

Successfully completed today:

You need a good 350mm pry bar with curved blade to get the banjo end lined up with the holes to get the front bolt in. I used a little 2Te trolley jack on wood blocks to support and push the banjo end then eased it around with a pry bar to get the holes aligned. Requires patience & persistence. Also good to file the cr*p & oxidation off the insides of the chassis bracket and apply a little lithium grease to allow the central alloy bush to slide between the faces easily. The banjo end tends to twist slightly when the ball joint end is tightened, meaning the central alloy bushing in the rubber is not parallel within the chassis bracket faces, so easy to chew into the alloy bracket faces or bushing faces. A good handheld light and a little mirror are essential to “see” what’s going on inside the bolt holes to get the holes lined up properly. Jack up, pry down, and you’ll probably need to pry the new banjo backwards by jamming something in front of it (hammer handle) and prybarring it rearwards. I did wonder if my aftermarket bars were too long, but its just the way the suspension moves with all the jacking etc. Persistence and patience required in spades! The above tool is superb, built like a brick sh*thouse, sadly can’t confirm if will fit L322, sorry! “If it ain’t broke, don’t fix it” -where’s the fun in that? |

||||

|

| Gremlin500 Member Since: 11 Mar 2022 Location: Newcastle, UK Posts: 1667

|

Hi, I thought the following pics may be useful in helping others make a decision whether or not to purchase this tool. My verdict is, it’s a shame the hydraulic ram didn’t go on the bottom arm, rather than from the top, however its such a strong tool even just using the supplied screw gets the job done in seconds:

|

||||

|

|

|

| All times are GMT + 1 Hour |

< Previous Topic | Next Topic > |

Posting Rules

|

Site Copyright © 2006-2025 Futuranet Ltd & Martin Lewis

![]()