| Getting ready to overhaul L322 BMW era front diff | |

I've been having some time what I believe is front differential whine.

So, to beat the bullet I ordered used differential from the ebay.

The idea is to overhaul this unit to perfection  and then install the unit into the car. and then install the unit into the car.

So far the with process:

Dismantled the differential, so no turning back.

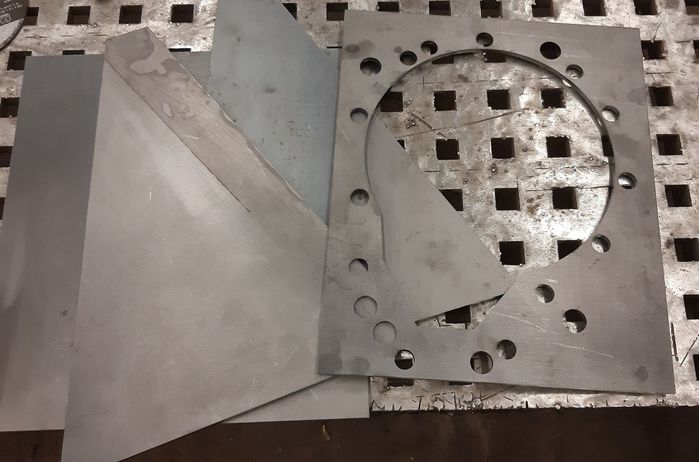

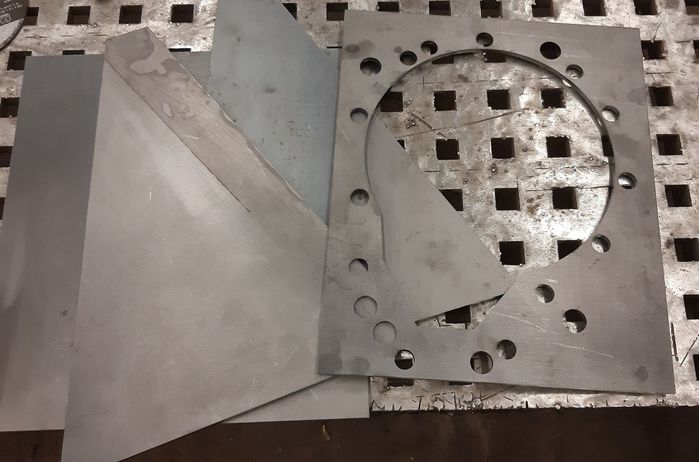

Laser cut some metal plates.

Last night was able to peel of the bearings from the pinion and the crown wheel (?).

| | Click image to enlarge |

| | Click image to enlarge |

with the help of this set.

First took out the outer cages of the bearings. Taking a grip of the inner body of the bearing was easier job. They are super tigtht!

If you are wondering, what the laser cut plates are doing, they are for the assembly process.

This is copied directly from the manual. With this stand bearing cup can be bench pressed and also this unit can be secured to the bench vice easily to make the super accurate tightening of the pinion nut easier to manage.

I have the torque dial wrench ready, as I do with complete bearing and gasket set not to forget crush sleeve.

| | Click image to enlarge |

|

![]()