| Home > Maintenance & Mods (L322) > 4.4 TDV8 Oil Cooler gaskets change - my attempt and tips |

|

|

|

| GraemeS Member Since: 06 Mar 2015 Location: Wagga area Posts: 2554

|

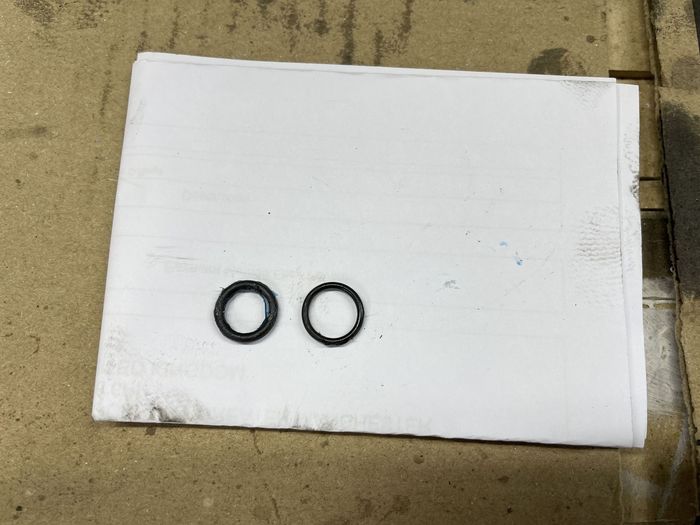

Presumably your new gaskets are the later versions so there's just a little hope that they won't need replacing again, especially with the sealant. The new gaskets weren't available when I did mine, also fitted with sealant hoping to make them last longer. Mine's EGR was disabled several months ago so hopefully without hot exhaust gases the oil cooler won't get so hot. |

||

|

| KristoffL322 Member Since: 20 Jun 2022 Location: North West Posts: 27

|

Yeah I bought the new style gaskets, so fingers crossed.

|

||

|

| GraemeS Member Since: 06 Mar 2015 Location: Wagga area Posts: 2554

|

ECM was remapped to stop the EGR opening in normal operation. I intend fitting a blanking plate. |

||

|

| KristoffL322 Member Since: 20 Jun 2022 Location: North West Posts: 27

|

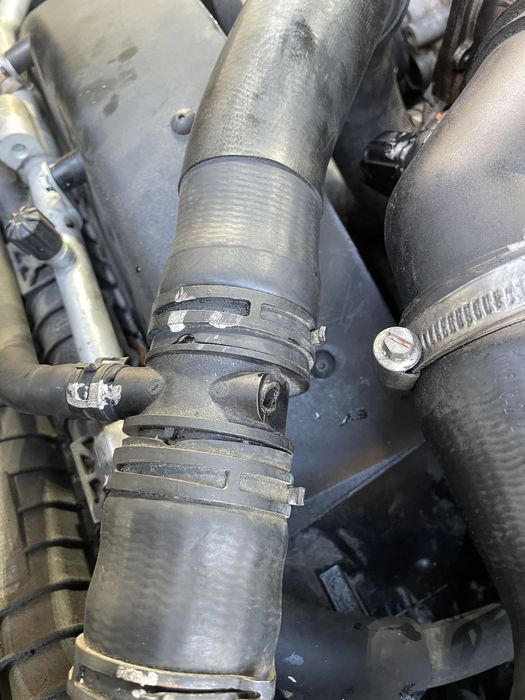

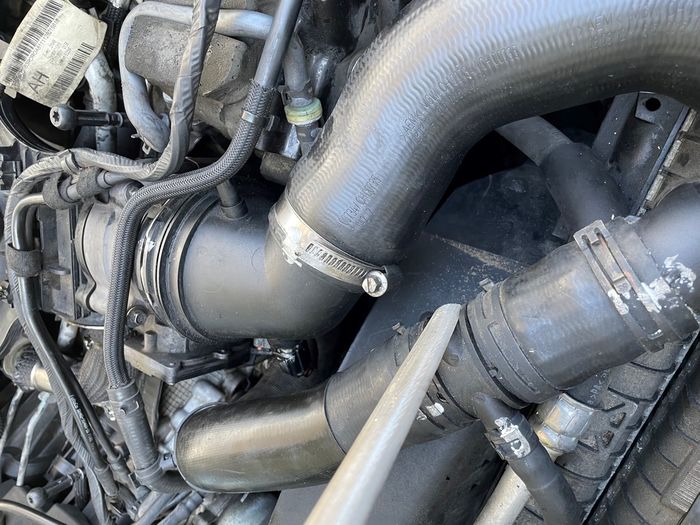

So today I attempted to fix the broken water pipe by fitting a threaded barb fitting, with mixed results.

|

||||||||||||||||||||||||||

|

| JayGee Member Since: 27 Jul 2021 Location: London Posts: 3283

|

|

||||

|

| KristoffL322 Member Since: 20 Jun 2022 Location: North West Posts: 27

|

That’s a nice solution. I don't own a lathe unfortunately.

|

||||||

|

| Haylands Member Since: 04 Mar 2014 Location: East Yorkshire Posts: 8358

|

I note you copied the original but I wonder why they made it with the barbs the wrong way round...!!! Or am I cracking up... Pete I now have permission from the boss to use Y.O.L.O. Enjoy life __________________________________________________ 2014 L405 Autobiography SDV8 4.4 Loire Blue Ebony interior 2011 L322 Vogue SE 4.4 TDV8 Baltic Blue. Sold 2012 L322 Autobiography 5.0 Supercharged Ipanema Sand Sold 2002 L322 Vogue 4.4 V8 Epson Green (Fatty Offroader) Sold -Click for Project Fatty off roader- |

||||

|

| JayGee Member Since: 27 Jul 2021 Location: London Posts: 3283

|

Not only did they make the barbs the wrong way round but they made it so weak it would break with the slightest touch 2012 TDV8 Vogue (L322) |

||

|

| KristoffL322 Member Since: 20 Jun 2022 Location: North West Posts: 27

|

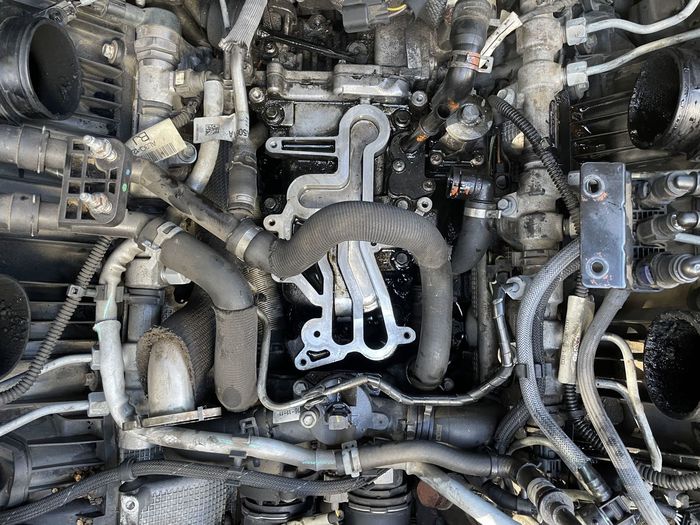

I had a good think about how to tackle this, as I don’t own a lathe, and its hard to find some of these small fittings in stock, from sellers that wouldn’t have me waiting weeks for delivery.

|

||||||||||||||||||||||

|

| KristoffL322 Member Since: 20 Jun 2022 Location: North West Posts: 27

|

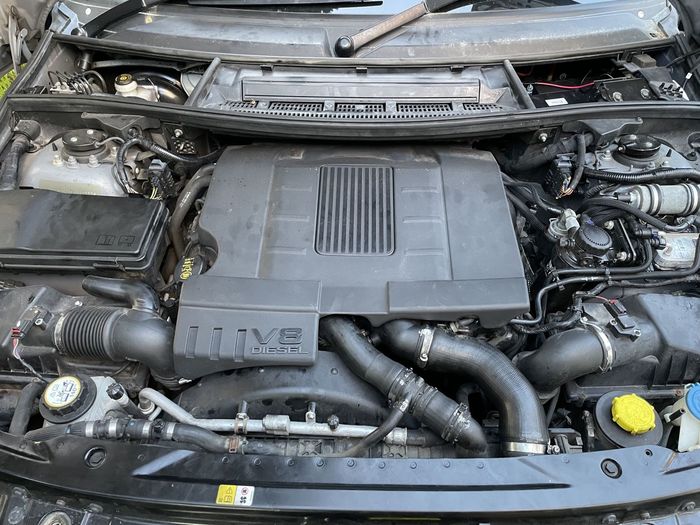

Happy to report that the cars all back together and running fine now with these fixes and the new oil cooler gaskets.

|

||

|

| pcourtney Member Since: 14 Jan 2020 Location: Stansted Posts: 836

|

smashing job, well done m8, something I really need to do soon as well - and thanks for the tips too |

||

|

| Merchy Member Since: 14 Feb 2021 Location: North Wales Posts: 1210

|

Cracking work there Sir, nice work on the pre-testing as well, always a good idea |

||

|

|

|

| All times are GMT |

< Previous Topic | Next Topic > |

Posting Rules

|

Site Copyright © 2006-2025 Futuranet Ltd & Martin Lewis

![]()