| Home > Maintenance & Mods (L322) > NO power (not limp mode) idle at 500rpm - now non starter . |

|

|

|

| Highroller Member Since: 18 Jul 2016 Location: Hampshire Posts: 565

|

If it runs then it's Not a Jumped belt. |

||

|

| Kot Member Since: 10 Mar 2021 Location: broadland Posts: 1197

|

Use the WIKI |

||

|

| AJGalaxy2012 Member Since: 11 Jun 2018 Location: Gainsborough Posts: 1464

|

I thought you said it wouldnt fire now with Easystart? BMW i3 Electric Car 2012 Full Fat RR 4.4 TDV8 (now gone) 2006 VW Touareg 3.0 TDi V6 |

||

|

| Kevhdkent Member Since: 27 Oct 2021 Location: Kent Posts: 69

|

I realise it sound crazy but this is the case.

|

||

|

| Kot Member Since: 10 Mar 2021 Location: broadland Posts: 1197

|

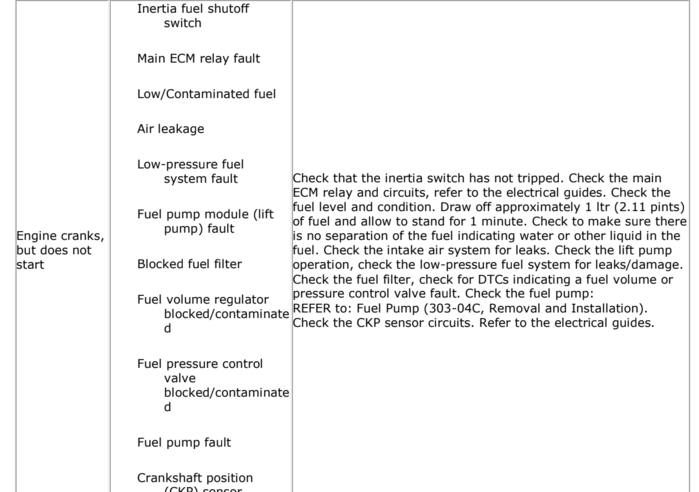

From WSM

|

||

|

| Kevhdkent Member Since: 27 Oct 2021 Location: Kent Posts: 69

|

I’m afraid it’s is way beyond my knowledge & experience, tho I can get the gist of it, and the timing position will be added to my short list of items for the engineer to be investigating on Monday. Thanks. |

||

|

| Spud Member Since: 12 Jul 2019 Location: Asif by Magic Posts: 130

|

I'll put 10 bob on a blocked exhaust. 2006 4.2 SC |

||

|

| Kevhdkent Member Since: 27 Oct 2021 Location: Kent Posts: 69

|

I’ll cover that Spud !

|

||

|

| Kot Member Since: 10 Mar 2021 Location: broadland Posts: 1197

|

My 10 bob |

||

|

| Spud Member Since: 12 Jul 2019 Location: Asif by Magic Posts: 130

|

Yes I've read the whole thread so far.

|

||

|

| Kevhdkent Member Since: 27 Oct 2021 Location: Kent Posts: 69

|

The fuel filter was only a few thousand miles old, and has been changed again as part of this process.

|

||

|

| Kevhdkent Member Since: 27 Oct 2021 Location: Kent Posts: 69

|

DTC’s have been accessed by 3 different parties, and none have found anything definitive |

||

|

| cass Member Since: 12 Oct 2011 Location: northumberland Posts: 732

|

I'm not normally a fan of buying bits and hoping it will fix it BUT when logic and common sense don't work I've repeatedly found that crankshaft position sensors have been to blame where there are intermittent and unpredictable problems.

|

||

|

| Kevhdkent Member Since: 27 Oct 2021 Location: Kent Posts: 69

|

Cheers Cass,

|

||

|

|

|

| All times are GMT |

< Previous Topic | Next Topic > |

Posting Rules

|

Site Copyright © 2006-2024 Futuranet Ltd & Martin Lewis

![]()