| Home > Maintenance & Mods (L322) > M62 5hp24 Gearbox issues |

|

|

|

| RRPhil Member Since: 22 Aug 2011 Location: Blackburn, Lancashire Posts: 993

|

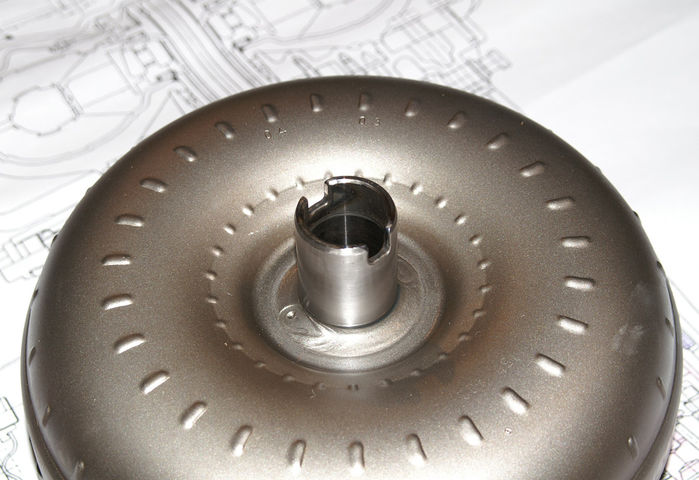

Yes, definitely. That’s exactly what I did with my L322. If you’re able to drop and re-install the transmission yourself, a remanufactured converter should set you back around £250-£300, but I’d recommend that you use a specialist supplier such as Sussex Autos or JPAT. Often you send your converter to them and they remanufacture your actual unit and return it to you within a couple of days. Phil |

||

|

| jbridges522 Member Since: 10 Mar 2025 Location: ni Posts: 2

|

Thanks Phil, I will scour the internet for removal guides. I believe it can be quite tricky to get the tc back in correctly, did you have any issue getting urs back in?

|

||

|

| RRPhil Member Since: 22 Aug 2011 Location: Blackburn, Lancashire Posts: 993

|

It’s critical that the slots in the torque converter impeller drive tube engage with the drive dogs on the oil pump gear

When you offer up the torque converter, and rotate it to line up the oil pump, you’ll hear a clunk and the torque converter will drop in. This is the tapered snout of the drive tube engaging in the cast iron seal and is not the oil pump drive engaging. You then need to keep turning the converter until it clunks and drops in for a second time and engages to the correct depth. Not difficult – just needs a bit of patience. To check that the pump drive is fully engaged you need to check the dimension from the face of the bellhousing to the four welded pads on the converter which take the flexplate bolts. This should be 25mm.

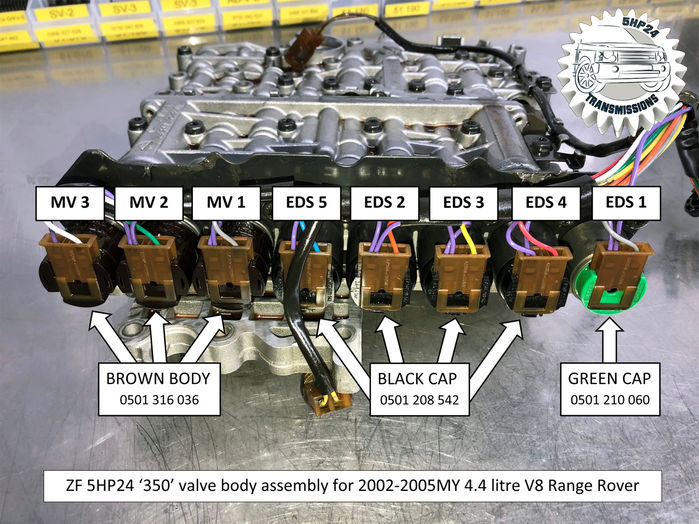

You could try swapping EDS 4 (which controls the torque converter lock-up clutch) with one of the other black-cap solenoids, just to eliminate it, but I doubt that’s the issue. You can check the resistance of the solenoid windings with a multimeter, but this only tells you if the winding is okay, and doesn’t tell you if the solenoid is functioning correctly hydraulically.

Phil |

||||||||

|

|

|

| All times are GMT |

< Previous Topic | Next Topic > |

Posting Rules

|

Site Copyright © 2006-2025 Futuranet Ltd & Martin Lewis

![]()