| Home > Technical (L405) > [448DT][SDV8] Connecting rod cap torque |

|

|

|

| 4RRS Member Since: 13 Apr 2022 Location: Crudgington Posts: 284

|

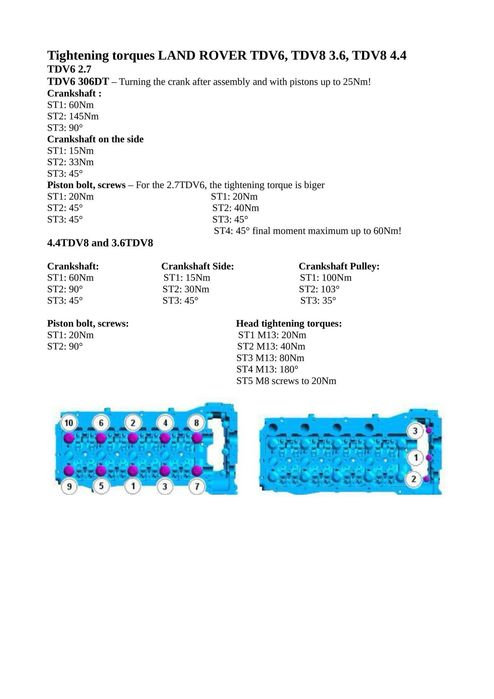

Here you go

|

||||

|

| szymonn Member Since: 10 Aug 2024 Location: Paniówki Posts: 7

|

Thank you so much. You saved my engine. On YouTube, it was said that the main crankshaft caps should be tightened to 60NM -> 140NM -> 90 degrees. Fortunately, I can still fix it. |

||

|

| 4RRS Member Since: 13 Apr 2022 Location: Crudgington Posts: 284

|

I used these settings when rebuilding my SDV8 nearly 30k ago and it's been fine. I used King heavy duty main and big end bearings with genuine crank and rods and it's been faultless.

|

||

|

| szymonn Member Since: 10 Aug 2024 Location: Paniówki Posts: 7

|

I've just started assembling it. Also on KING bearings. Also new pistons because there was a small hole in one of them |

||||

|

| 4RRS Member Since: 13 Apr 2022 Location: Crudgington Posts: 284

|

I also replaced pistons (.50 o/s). Remember piston rods are numbered due to weight balancing. I reused main bearing bolts and big end cap bolts as the aftermarket ones I bought didn't feel good when beginning to torque them. I understand they can be used 3 times, mine is fine so I guess that's true!

|

||

|

| GraemeS Member Since: 06 Mar 2015 Location: Wagga area Posts: 2624

|

Crankshaft side specs - is this referring to the 2nd bolt, furthest away from the crankshaft? Seems strange for both not to be the same though.

|

||

|

| 4RRS Member Since: 13 Apr 2022 Location: Crudgington Posts: 284

|

Crankshaft side specs relate to the main bearing cap cross bolts, the ones that go through the block horizontally into the caps.

|

||

|

| GraemeS Member Since: 06 Mar 2015 Location: Wagga area Posts: 2624

|

Thanks 4RRS for the explanation.

|

||

|

| szymonn Member Since: 10 Aug 2024 Location: Paniówki Posts: 7

|

I want to determine the correct thickness of the head gasket. Both cylinder heads have been resurfaced, but I don’t know by how much. Is my only option to rely on someone like you to measure the original thickness of the cylinder head and compare it to mine? Or do you have another proposed solution for this? |

||

|

| 4RRS Member Since: 13 Apr 2022 Location: Crudgington Posts: 284

|

There is no gasket available other than the std 4.4 thickness gasket so it's not possible to compensate for the refacing with a thicker gasket as you can with the 306DT engine. In my 4.4 engine rebuild thread I documented this, its a case of whatever was skimmed off the head, to then reseat the valves by the same amount to equalise the clearance, if you get this wrong you could end up with piston to valve contact at TDC. L405 SV Autobiography LWB SDV8, finished in Aston Martin China Grey by ETO division. |

||

|

| szymonn Member Since: 10 Aug 2024 Location: Paniówki Posts: 7

|

thanks for the advice. yes it was only surface treatment I hope it was the first one - I will check how the gasket was when I am in the workshop. as for WSM the description is for all engines just not for 448dt hence my question |

||

|

| 4RRS Member Since: 13 Apr 2022 Location: Crudgington Posts: 284

|

Please read my post again, as when I first posted I was thinking of the 306DT, not the 448DT and hence edited my post, which I suspect you haven't seen.

|

||

|

|

|

| All times are GMT |

< Previous Topic | Next Topic > |

Posting Rules

|

Site Copyright © 2006-2025 Futuranet Ltd & Martin Lewis

![]()