| Home > Maintenance & Mods (L322) > How To: P040D-00 - Replacing the Exhaust Temp Sensor 4.4TDV8 |

|

|

|

| garyRR Member Since: 13 Mar 2021 Location: Hampshire Posts: 1480

|

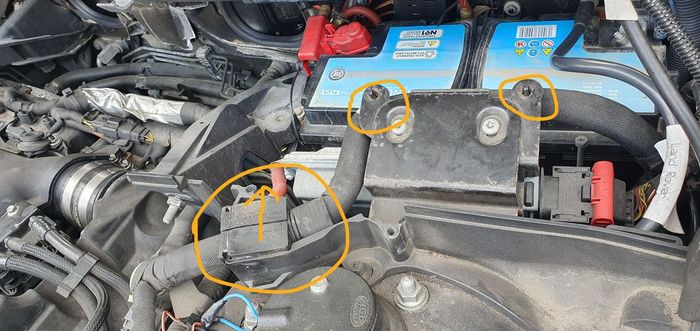

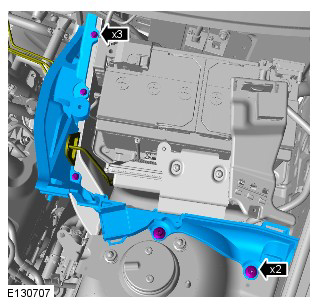

I thought I'd write a guide for anyone who has encountered the P040D-00 error or needs to visit this as a culprit as a result of the 'Restricted Performance' message on the dashboard for the 4.4 TDV8 or 4.4 SDV8 (this fix is largely the same for both the L322 and L405).

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

| Dolphinboy Member Since: 07 Dec 2009 Location: Bristol Posts: 3199

|

great work Gary. Many thanks for your efforts. |

||

|

| DrRob Member Since: 16 Apr 2015 Location: Petersfield, Hampshire Posts: 4325

|

One for the Wiki |

||

|

| stan Site Moderator Member Since: 13 Jul 2010 Location: a moderate moderated moderator moderating moderately in moderation Posts: 35515

|

it is .. |

||

|

| Cam-Tech-Craig Member Since: 03 Aug 2011 Location: Gloucestershire Posts: 16315

|

Can you believe the book time is less than 1hr on topix |

||

|

| Cam-Tech-Craig Member Since: 03 Aug 2011 Location: Gloucestershire Posts: 16315

|

I’ve refused to do them for a long time now! Take them to our local main dealer and they struggle to do them in 3-4hrs! With all the kit in the world BUT! Their hands are tied by JLR to follow topix procedures! So, yes I’m sure a good mechanic with experience in this job could hone their skills to reduce that time considerably…

|

||

|

| Tommybuk Member Since: 17 Jan 2024 Location: Ellon Posts: 13

|

I tackled the EGT on the left manifold today on a 2016 L405.

|

||

|

| pcourtney Member Since: 14 Jan 2020 Location: Stansted Posts: 882

|

Even 1 hour using Topix guide would be £200 at a main dealer, I guess its swings and roundabouts |

||

|

| GGDR Member Since: 26 Nov 2016 Location: London Posts: 3551

|

different engine bay on the L405 so access is very different. sounds a lot better. the complexity to this job is the access on the L322. Interested to hear the sensors are still dying as late as 2016 Cheers, Greg - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2011 Vogue SE 4.4 with lots of toys in Stornaway |

||

|

| garyRR Member Since: 13 Mar 2021 Location: Hampshire Posts: 1480

|

My 2025 L405 has the code, which the previous owner took to main dealer and I quote from the receipt (i think it was in for something else):

|

||

|

| Tommybuk Member Since: 17 Jan 2024 Location: Ellon Posts: 13

|

The fault codes on my 2016 L405 were different to what is reported on this post. It was on changing the manifold sensor, however, that cleared the fault in the end.

|

||

|

| dpm Member Since: 14 May 2018 Location: grimsby Posts: 41

|

I'm doing this job and got the retaining nut off the old sensor, the stub of the old sensor feels loose and i can wiggle it but it won't pull out, any idea what is holding it in ? |

||

|

| Tommybuk Member Since: 17 Jan 2024 Location: Ellon Posts: 13

|

From memory it's just seated in the manifold. Mine just wiggled out after I got the nut off. Maybe leave it soaked in wd40 overnight and try again. Last thing you want is to break the probe off in the manifold.

|

||

|

| GGDR Member Since: 26 Nov 2016 Location: London Posts: 3551

|

once the nut is off there is nothing holding it on but heat may have stuck it in place. as said above WD40 soaker suggested

|

||

|

|

|

| All times are GMT |

< Previous Topic | Next Topic > |

Posting Rules

|

Site Copyright © 2006-2025 Futuranet Ltd & Martin Lewis

![]()