|

After receiving no responses from anyone with experience, I decided to proceed carefully - it wasn't going to fix itself !

Just in case anybody has the same problem, here's what I ended up having to do to resolve the problem - a bit long for completeness !

I discovered that by removing the plastic engine top cover & cabin filter housing I could lie on the top of the engine (not comfortable - lol) and get a hand down the back of the engine and feel the broken pipe end & the flange retaining bolt heads.

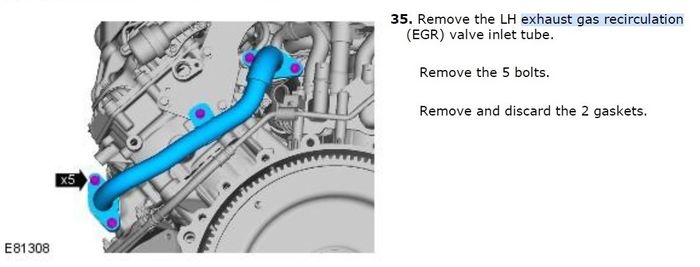

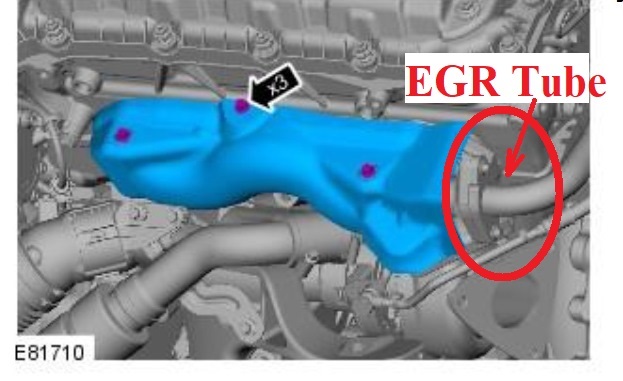

The EGR pipe was in the way for tool access - but fortunately could be removed after removing a small supporting bracket behind the block & removing the 2 retaining bolts on the EGR. My EGRs are mechanically blanked at the inlet manifold side, so the EGR pipe wasn't going to be refitted !

With the EGR pipe gone & 2 heater hoses tied back out the way, there was just enough space to get in with a 1/4" drive ratchet, short extension & 8mm socket. The upper bolt head could just be seen through a gap in the various parts. The lower bolt was invisible.

Jubilee clip tangs sticking out on what I think was a heater control valve made hand removal very painful & was eventually overcome with thick chunks of "tank" tape & 2 pairs of rubber gloves !

Unfortunately, the ergonomics were so bad I was really afraid the socket would slip off the bolt heads & round them off - making removal impossible as there was no access for bolt extractors, drills etc.

I changed to a 6 sided socket rather than bi-hex, hoping for a tighter fit - but it was still loose.

A sudden thought was that the "socket" holding a 8mm hex bit might be better & after extracting the hex bit, I had a 6 sided socket that was a good fit.

Initial attempts at loosening the bolts confirmed my worse fears - they were very, very tight & / or corroded in. I decided there was a very high risk of breaking the bolt heads off - resulting in an unusable car without dropping the engine far enough to get better access for extraction tools (would have to be dropped 6 inches plus  ) )

Decision made - 5 days of repeated spraying with XCP penetrating oil . Only possible from underneath the car unfortunately !

After 5 days, I tried loosening the upper bolt & finally it started to move (at much lower effort than I'd tried 5 days previously !) & then could be extracted (about a 1/4 of a turn max at a time). The lower bolt also loosened, but was tight all the way out - damaged thread ?

With the bolts out I could remove the EGR pipe retaining flange & use it to make a thin metal blanking plate to be retained by refitting the flange

I forgot to take a photo - but it was same shape as the flange, but obviously without the central hole.

I managed to get an M6 tap into the lower bolt hole with a small hand chuck & clean up the thread

The "old" flange was then used to retain the new blanking plate with a smear of exhaust paste to help it seal & a change to internal hex head bolts to make tightening less risky.

Finishing off then just required removal of heater hose tie-backs, jubilee clip protection & refitting the cabin filter housing & engine cover - job done & engine sounding refined again.

The failed EGR pipe looks badly made. It looks as though the pipe is a force fit in the flange - maybe swaged in & possibly a single spot weld to hold them together - a recipe for a vibration induced failure.

My car is amongst the first with the 3.6TDv8 & interestingly the part number of the pipe appears to have changed ! Maybe Land Rover realised the design was no good & changed it sometime later.

| | Click image to enlarge |

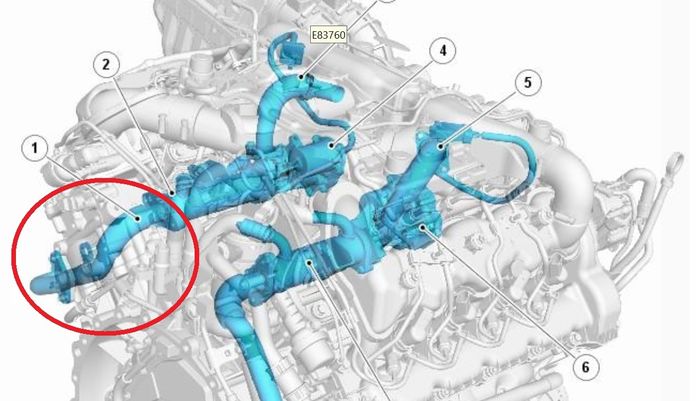

When I've got time in the Summer (ie warmer) I'll remove & blank off the EGR pipe on the RH bank of the v8 - as I assume design will be as bad. At least access looks slightly easier (same issues, but less bruised hands  ) Paul, ) Paul,

2001 Discovery 2 TD5, 211,000 miles & climbing

2006 FFRR TDV8 Vogue 151,000 miles & now sold

Member of Midland (Land) Rover Owners Club, www.mroc.co.uk

|

![]()