| Home > Maintenance & Mods (L322) > Rear Drive Axle Seal replacement L322 RR 2006 |

|

|

|

| GraemeS Member Since: 07 Mar 2015 Location: Wagga area Posts: 2654

|

I replaced the axle seals in mine's rear diff without using the special tool. The tool is meant to expand the seal to prevent the outer dust seal lip from turning in but this was not an issue for me. The drive-shafts are stepped to allow the splines to be engaged before the larger diameter for the seal seat gets to the seal. The shaft is correctly aligned and supported before the larger dia section meets the seal.

|

||

|

| Blue Hornet Member Since: 25 Sep 2018 Location: Sawtell Posts: 17

|

Hi Graeme

|

||

|

| GraemeS Member Since: 07 Mar 2015 Location: Wagga area Posts: 2654

|

As far as I can tell, the tool is a single-use cup that fits inside the seal then is broken from around the drive-shaft once the shaft is inserted far enough that the seal will expand onto the shaft seal area. However even the genuine LR seals that I purchased didn't include the fitting tool so I assume that the tool is not required.

|

||

|

| Blue Hornet Member Since: 25 Sep 2018 Location: Sawtell Posts: 17

|

|

||||||||||

|

| GraemeS Member Since: 07 Mar 2015 Location: Wagga area Posts: 2654

|

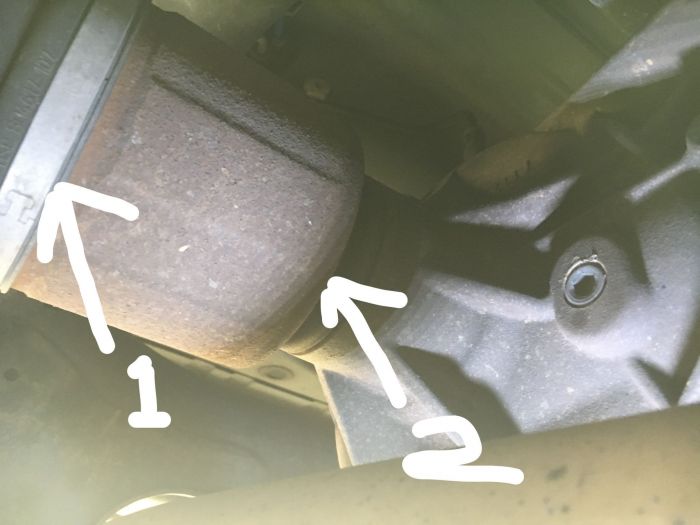

Yes that looks to be the later drive-shafts and the later open diff. I had to remove the inner joint from the diff because I was fitting an e-diff but you could instead undo the boot clip on the inner joint which would then slide apart, providing that you had another clip or large hose clamp in case you couldn't get the original done up again. When changing a front boot on my son's D4 we couldn't apply enough force to release the inner joint from the diff so disassembled the inner joint instead. It was a bit messy to refit but straight-forward. The inner joint's shaft is retained in the diff by a clip on the drive-shaft that expands into a groove in the diff gear which then requires considerable force to cause it to compress to slide back out along the splines.

|

||

|

| Blue Hornet Member Since: 25 Sep 2018 Location: Sawtell Posts: 17

|

Thanks Graeme

|

||

|

| GraemeS Member Since: 07 Mar 2015 Location: Wagga area Posts: 2654

|

The clip that you identify at arrow 1 can be undone, after which the boot can be pulled back from the joint's outer casing which then allows the drive-shaft to be withdrawn. However the clip is normally pulled tight then bent back over the slot through which the free end passes, side tabs bent over the turned-back end then the excess trimmed. Without the excess the clip may still be able to be pulled tight using pliers, but can be a fiddly task. |

||

|

| Blue Hornet Member Since: 25 Sep 2018 Location: Sawtell Posts: 17

|

OK thanks Graeme

|

||

|

|

|

| All times are GMT + 1 Hour |

< Previous Topic | Next Topic > |

Posting Rules

|

Site Copyright © 2006-2025 Futuranet Ltd & Martin Lewis

![]()