| Home > Maintenance & Mods (L322) > FFRR '02 Rear Suspension Dismantle & Rebuild |

|

|

|

| Joe90 Member Since: 29 Apr 2010 Location: Hampshire Posts: 6432

|

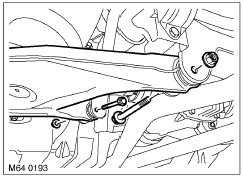

Been gathering parts and bits and pieces for this for a while, and some leave from work has provided me with the opportunity to dismantle my rear suspension and replace all the bushes, tie rods and links. Airbags and dampers are OK, but these are the easier items to remove!

|

||

|

| Joe90 Member Since: 29 Apr 2010 Location: Hampshire Posts: 6432

|

1. Get the car in the air.

|

||||

|

| Joe90 Member Since: 29 Apr 2010 Location: Hampshire Posts: 6432

|

Got an earlier start today, out there by 0830 |

||||||||||

|

| Joe90 Member Since: 29 Apr 2010 Location: Hampshire Posts: 6432

|

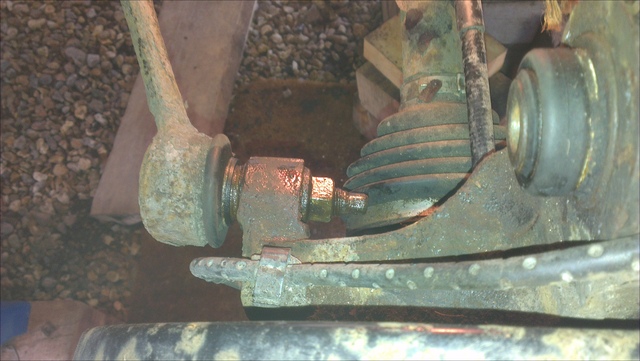

Had a few other real world things to do today so not a great deal done, but time consumed by problem ball joint!

|

||||||

|

| Joe90 Member Since: 29 Apr 2010 Location: Hampshire Posts: 6432

|

Bush pressing kit arrived today, so set to work on pressing out and replacing all the bushes on the hub, the arms and the subframe. It is a lot bigger than the ebay picture conveys, ( I put a standard Stanley Philips screwdriver in shot to give scale) case is @ 48cm wide by 40cm deep, and weighs @ 40lbs. As impressed as fisha was - the mutts nuts!!

|

||||

|

| Joe90 Member Since: 29 Apr 2010 Location: Hampshire Posts: 6432

|

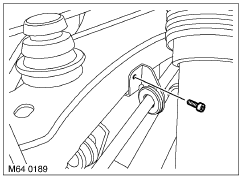

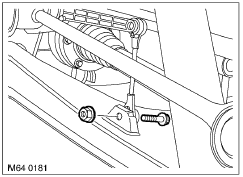

1. Finish Removing Lower Arm Bushes

|

||||||||||||||||

|

| Joe90 Member Since: 29 Apr 2010 Location: Hampshire Posts: 6432

|

1. Hub Bushes Replaced

|

||||

|

| Joe90 Member Since: 29 Apr 2010 Location: Hampshire Posts: 6432

|

Bloody cold today, snowed on me several times

|

||||

|

| Googsy Member Since: 02 Jun 2011 Location: Where men are men and sheep are nervous. Posts: 2947

|

Joe your a legend I kind of follow what your doing as it seems complex but I admire your persistence with such a big project |

||

|

| Joe90 Member Since: 29 Apr 2010 Location: Hampshire Posts: 6432

|

Took a day of rest today, fed up with spending all day on my knees in the freezing cold.

|

||

|

| Joe90 Member Since: 29 Apr 2010 Location: Hampshire Posts: 6432

|

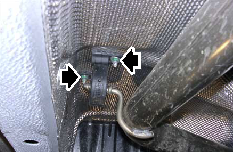

Damn I have an air leak.

|

||

|

| Joe90 Member Since: 29 Apr 2010 Location: Hampshire Posts: 6432

|

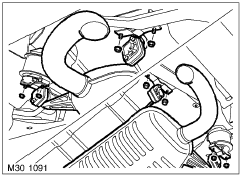

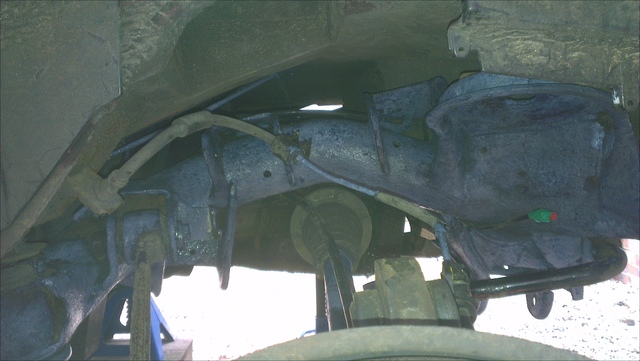

Took on the Rear Right today with good weather promised for the weekend. Didn't get started until @ midday and finished @ 8pm. Most items appeared to undo much easier on this side as compared with the rear left, or I've got stronger! I took quite a different approach this time, based upon what had been learned from the other side.

|

||

|

| Joe90 Member Since: 29 Apr 2010 Location: Hampshire Posts: 6432

|

Nice sunny morning 10 am start!

|

||||

|

| Joe90 Member Since: 29 Apr 2010 Location: Hampshire Posts: 6432

|

MON

|

||

|

|

|

| All times are GMT + 1 Hour |

< Previous Topic | Next Topic > |

Posting Rules

|

Site Copyright © 2006-2025 Futuranet Ltd & Martin Lewis

![]()