|

Well, I decided to take a flier and install the driveshaft as it was as the boot felt secure. Sadly, just the action of moving the shaft to engage the hub was enough to make the boot slip off. Gggrrrr.

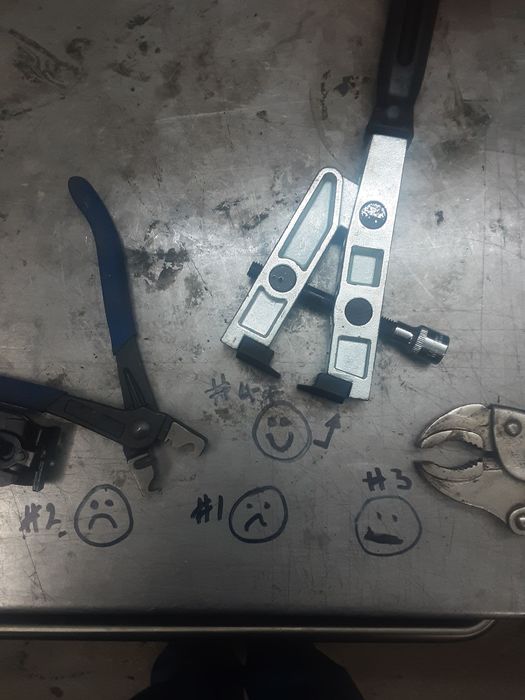

I plumped for a suitable looking tool and boy did it make it easy to apply the tension to the boot clamp. All seems good thankfully but will keep an eye on it for a while.

Incidentally, getting the driveshaft out of the hub was a heck of a job, which ended up with the upright in the 20 ton press. Took some pressure to get it out. My air hammer wasn't anywhere near strong enough and my big puller not big enough!

I figures getting it back in was going to be troublesome so went the drill and tap the driveshaft route (thanks to whoever here shared who shared that tip) and needed to apply quite some effort to draw it in with a slide hammer.

All good, I think.

Updated pic of tooling!

Chris

| | Click image to enlarge |

|

![]()