|

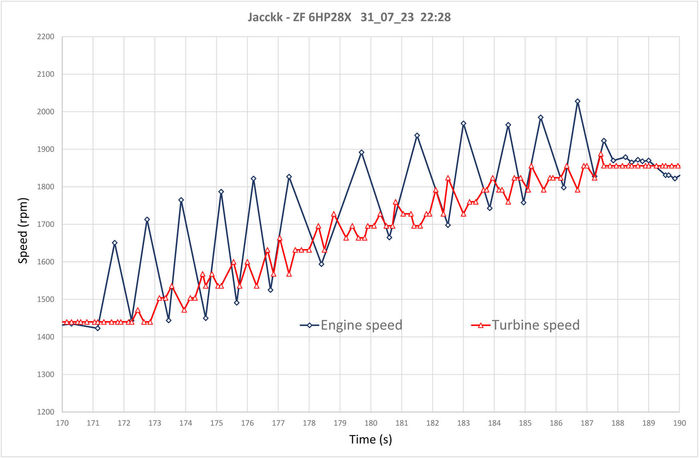

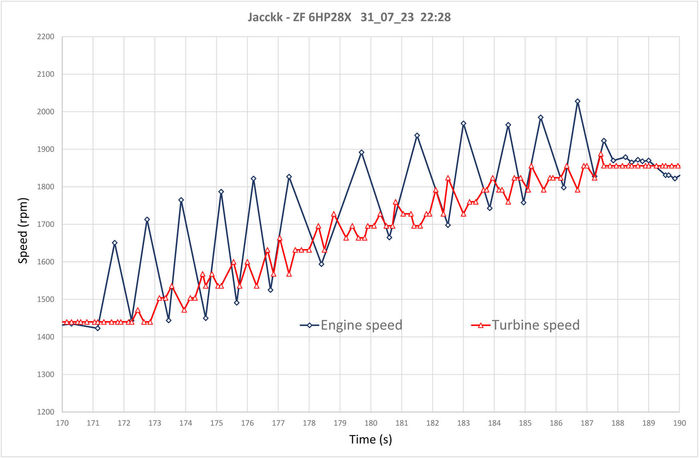

Unfortunately, during the important bit, the resolution on the engine speed measurement is only around 1Hz, whereas for the turbine speed it’s around 6Hz. This makes it difficult to decide, just looking at the graph, whether the engine ‘judder’ is real or not.

I wondered if it might be possible to capture the vibration again while recording engine speed, turbine speed and the EDS2 solenoid current, not bothering with the vehicle speed for now to hopefully improve the data capture rate?

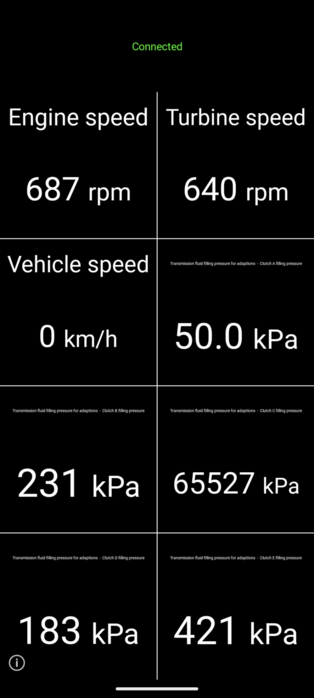

As you mentioned, the charge pressure adaptions indicated by the IIDTool for the 6HP28 appear to be complete gibberish. For example, 421kPa is a 4.21 bar ‘adjustment’ to a solenoid which operates off a modulated (constant) 5 bar supply.

Phil

|

![]()