| Home > Maintenance & Mods (L322) > Lower arm replacement |

|

|

|

| GGDR Member Since: 26 Nov 2016 Location: London Posts: 3552

|

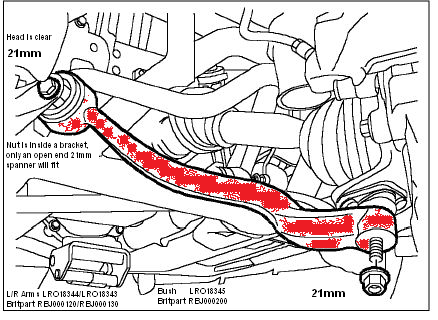

...isn't possible without removing the calliper which a) I'm too lazy to remove and b) needs a multi-point socket which I don't have Plus I think this might damage the rubber of the cassette ball joint which I'm not changing. I now know there isn't really much bashing room to try a lump hammer removal technique. So I want to get a puller - well a pusher really - something that will push up on the nut underneath while hooked onto the arm. Quite a bit of work for a part that is help in by two bolts. How hard could that be? Any tips for a pushing tool? . Cheers, Greg - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2011 Vogue SE 4.4 with lots of toys in Stornaway |

||||

|

| northernmonkeyjones Member Since: 24 Mar 2012 Location: derby Posts: 8749

|

Big hammer....

|

||

|

| GGDR Member Since: 26 Nov 2016 Location: London Posts: 3552

|

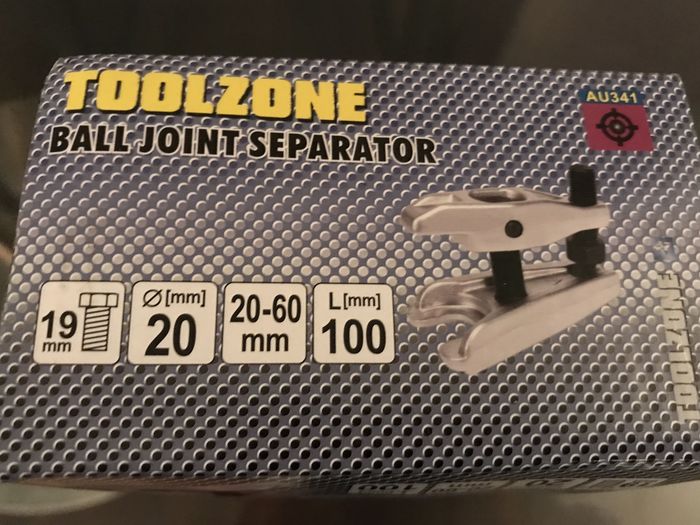

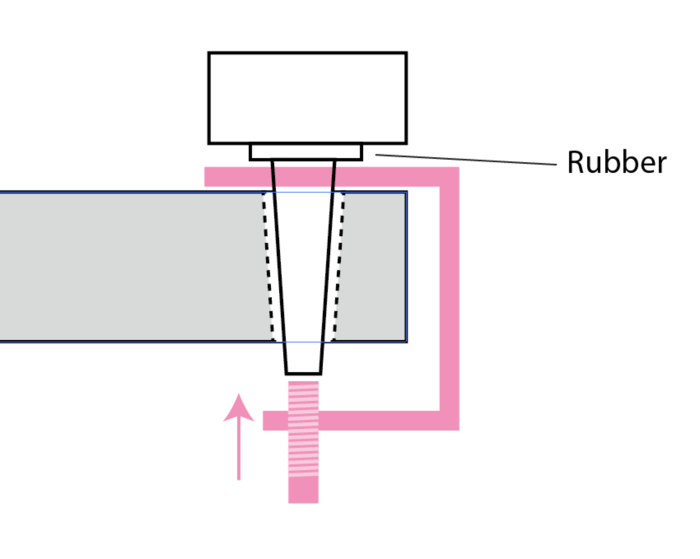

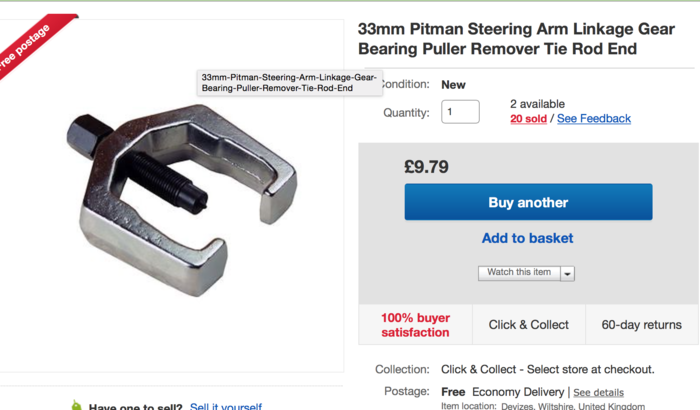

Looking at these

The black pin pushes up on the ball joint's bolt (+nut on) while the forks hook onto the arm then pull against the arm but not the rubber - if I am thinking correctly.. Like this:

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2011 Vogue SE 4.4 with lots of toys in Stornaway |

||||||

|

| northernmonkeyjones Member Since: 24 Mar 2012 Location: derby Posts: 8749

|

Worth a try, there’s not a lot of space between the rubber and the arm but they look quite slim. There is nothing that can't be fixed with a hammer😜😜

|

||

|

| GGDR Member Since: 26 Nov 2016 Location: London Posts: 3552

|

Bought this and it did work perfectly.

If anyone wants to just do the arm and leave the cassette ball joint then go for this type of tool: I hooked it on the arm facing down, the wide claws well away from the rubber boot on the topside, wound up at the nut and with a swift belt from a hammer, the taper popped. No fuss and super quick. As with most jobs, it's all about the right tools. I thought I'd leave the nut on the bottom for stability and thread protection but turned out to be a schoolboy error as the ball just spun and spun trying to get the nut off. No biggie, returning a bit of pressure from underneath with a jack was enough to wind the nut fully off. Since I had a go at this already, the WD40 sprayed last week paid off and the bolts otherwise came off easy. bgennette's comments about a block and tackle got me thinking I'd struggle, the hub does indeed pull away by an inch and you need to get it back to re-insert the bolt but actually with a jack stand and turning the steering to the opposite lock I got the holes lined up pretty nicely without any hub pulling or jacking. Setting the hub centre height to torque it to correct tension is indeed a bit of a phaff, at least for me - I'm working on the street but managed it. I'd suggest setting height to 'normal' before you start as I had it in extend mode for access but I had to adjust it up and down but the car kept detecting the axle stands thinking it was grounded and raised it even higher. bgennette's comments about trimming the arch liner were spot on and helped. Thanks Mark too. Only got one side done today as limited time during pre-christmas madness but the other side will be definitely quicker now I've done one. Most things are quicker the second time right? I wasn't planning to replace cassette ball joint as I had a really good multi-directional pull & push with a bar before I planned this job - and thankfully the cassette ball joint felt good and smooth with the arm off it. But the old rubber bush in the arm was certainly shot:

It's a weird suspension link if you ask me, the centre spindle is clamped in and not designed to rotate, leaving the rubber to spokes to stretch and flex thought the long suspension travel. Not sure what benefits this set up has vs a more usual rubber bush that allows normal rotation. One question for the panel, why do you torque a nut then add a quarter turn? Why not just torque it to a higher Nm ? . Cheers, Greg - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2011 Vogue SE 4.4 with lots of toys in Stornaway |

||||||

|

| northernmonkeyjones Member Since: 24 Mar 2012 Location: derby Posts: 8749

|

Yep, that looks scoobied...... There is nothing that can't be fixed with a hammer😜😜

|

||

|

| Goldstar Member Since: 04 Dec 2021 Location: Reading Posts: 118

|

Thanks to all the previous contributors logging their experience I was able to do this job in 20 minutes today. Didn't need to take the caliper off. I loosened the arm at the bush end (21mm spanner as previously mentioned by others) and then the nut at the top of the ball joint (also 21mm) I then took my FBH and gave the ball joint housing a few (about a dozen) whacks and the taper went pop.

|

||

|

| kevinp Member Since: 28 Sep 2019 Location: Telford Posts: 1293

|

Goldstar, did you remember to tighten the suspension arm nuts with the weight of the car on it's wheels? |

||

|

| Goldstar Member Since: 04 Dec 2021 Location: Reading Posts: 118

|

Good question. Belt and braces - I jacked the hub up to the correct height and tightened there first then checked the nut again after a test drive. Dec 2021- 2010 Facelift TDV8 4.4 AB in Stornoway Grey. |

||

|

| Goldstar Member Since: 04 Dec 2021 Location: Reading Posts: 118

|

I probably ought to anyway as I don’t know when it was last done but do I “need” a tracking check after changing this arm?

|

||

|

| Phoenix Member Since: 16 May 2022 Location: Gone Posts: 1631

|

As there is no adjustment points on it, then no. In practice, the bushes will be tighter so could pull everything in a bit. Think of how much an unevenly worn tyre will cost to replace vs. the cost of a wheel alignment

|

||

|

| kevinp Member Since: 28 Sep 2019 Location: Telford Posts: 1293

|

My track rods had to be turned in a total of one turn to bring the wheels back in line after changing my lower arms so I would if I were you. |

||

|

| Goldstar Member Since: 04 Dec 2021 Location: Reading Posts: 118

|

Booked in for Friday. Thanks chaps Dec 2021- 2010 Facelift TDV8 4.4 AB in Stornoway Grey. |

||

|

| bgennette Member Since: 13 Jan 2013 Location: Newcastle Posts: 88

|

One question for the panel, why do you torque a nut then add a quarter turn?

|

||

|

|

|

| All times are GMT + 1 Hour |

< Previous Topic | Next Topic > |

Posting Rules

|

Site Copyright © 2006-2025 Futuranet Ltd & Martin Lewis

![]()