|

while cleaning MAP sensor and throttle body butterfly i manage to break this small pipe.

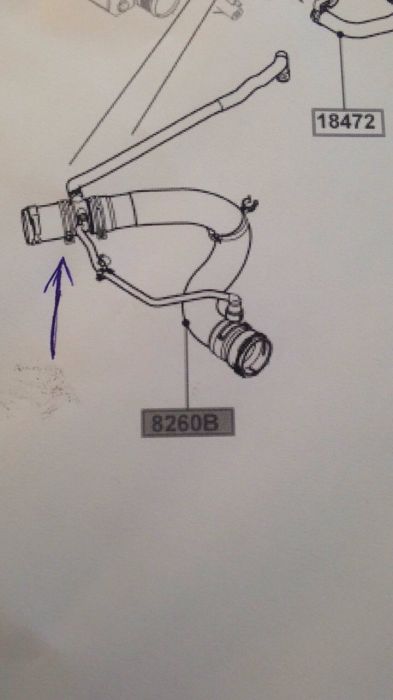

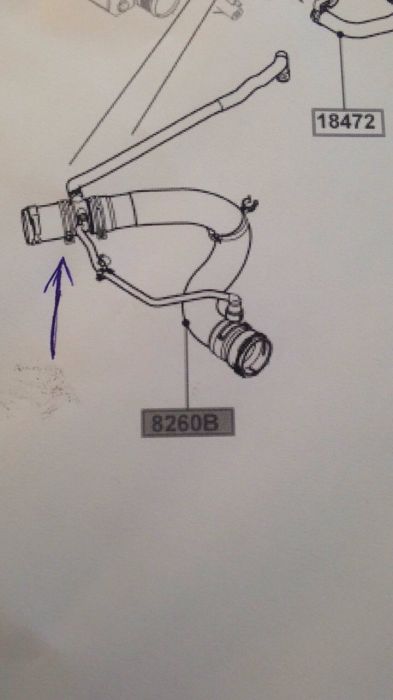

in the picture green is the pipe and red is the plastic T where the pipe connects. in order to get plastic pice you have to bay all this:

| | Click image to enlarge |

so i set out to try and fix this and this is what i did.

these are the things i used for repair:

#1 - thin wall brass tubing OD 7mm length ~43mm (hobby shops have them)

#2 - gasket grade silicon

#3 - Q tips

#4 - shrink tubing OD 13mm

#5 - silicon lubricant spray

#6 - custom made drill bit.

first i broke the pipe clean off and than enlarge the hole on both ends, first with 6.5mm drillbit and then special drillbit made from same 7mm brass pipe.

clean the brass tube with emery cloth or sandpaper apply little bit of super glue(gel) on one end and twist and push it in the plastic pipe. now slide shrink tubing (35mm length 13mm OD) over the plastic pipe and let it overhang 8~10mm over brass tube.

now carefully shrink the tubing on the very end where it goes over plastic pipe (use heat gun or cigaret lighter) so it fits tight.

with this we created the packet in which to squeeze silicon. with silicon in start shrinking that end now (we are trying to make silicon sausage) with the end of the shrink tubing tight to brass tubing apply heat to the middle. with this, one end is finished

now use small Qtip to apply silicon inside the hole that is going to receive brass tubing and twist and slide brass tubing in so it looks like this-

there should be 5~7mm of brass tubing left between plastic pipe and plastic T. apply thin layer of silicon over brass and where it enters plastic T. let this dry for few hours (i let my sit for 3 H. in the midday sun). after that apply liberal coat of silicon so it looks like in picture. let it dry to a tuch and reassemble. all done.

to work on those strong spring clips i modified my players with dremel tool.

and in the end bleed the air here

and at the expansion tank (bleed valve is somewhat hidden under this two pipes)

Hope this helps.

|

![]()